No matter the size of your eCommerce business, proper inventory management is critical to your store. It offers a number of benefits to both you and your customers and leads to increasing sales and skyrocketing your revenues in the long run. And as your business scales and grows into a larger facility, so does the need for efficient inventory management. And dedicated software can assist you in achieving this goal. But let’s go over everything in order.

Read on to learn about the basics of inventory management, its importance, methods, techniques, KPIs, and tools to keep track of your goods easily with minimum effort from your side while saving time and money.

Key points

What is inventory management and why is it significant?

At its most basic, inventory management is how you organize — order, store, sell, and move — your stock. It helps you track the amount and location of all the items shoppers can buy from you. Its aim is to ensure your eCommerce business has the necessary amount of goods at the right time and in the right place. This enables merchants to get products into their customers’ hands as quickly as possible.

By failing to manage your inventory properly, you can face such risks as overstocks, shortages, out-of-stocks, mis-shipments, mis-picks, spoilage, etc. The list could go on further. All this will definitely make your customers frustrated and result in your business losing revenue. Did you know that poor inventory control can cost your business an astronomical amount of money each year — $1.1 trillion? Sounds impressive, right?

Let’s take a look at the major benefits you can reap with proper inventory control:

- Efficient data-driven goods planning. If you don’t know how many items there are in stock already and order a new batch of them, you can run into overstock. And if these products are not your bestsellers you are likely to end up investing money in vain. Moreover, you leverage your space ineffectively. Good inventory management helps you mitigate such risks.

- Accurate order fulfillment. Imagine a retailer’s nightmare: a customer places an order happily and then discovers the necessary product is out of stock or — what’s even worse — shipped to the wrong location. Poorly managed inventory will finally result in lower customer satisfaction, higher revenue volumes, and revenue losses.

- Increased customer loyalty. By making your store visitors happy with excellent customer service, you increase the chances to get more loyal customers who will come back to make a purchase over and over again.

Looking for a reliable eCommerce development vendor? Feel free to reach out to us and we’ll discuss your project gladly.

Types of inventory

Before you get down to effective inventory management, you need to actually understand what inventory typically comprises. Here’s the list of the most common types of inventory:

- Raw materials/substances

- WIP (Work-in-progress)

- Finished goods

- MRO (Maintenance, repair, and operations goods)

Let’s dive into each in more detail.

Raw materials/substances are used for manufacturing goods. These include wood, fabrics, plastic, metals, etc. to produce finished goods.

Work-in-progress (or goods-in-progress) are sometimes called semi-finished goods. Basically, those are raw goods that are partially processed and are awaiting completion.

Finished goods are actually final products that are ready to be sold. They are obtained once a WIP is complete.

Maintenance, repair, and operations goods (MRO) are consumables, supplies, and equipment used to support materials that take part in the production process. For example, lubricating oil, repair tools, stationery, face masks, tech equipment, cleaning supplies, etc.

Now that we’re familiar with different types of inventory, let’s look at inventory management techniques you can use to improve accuracy and remove as much human error as possible.

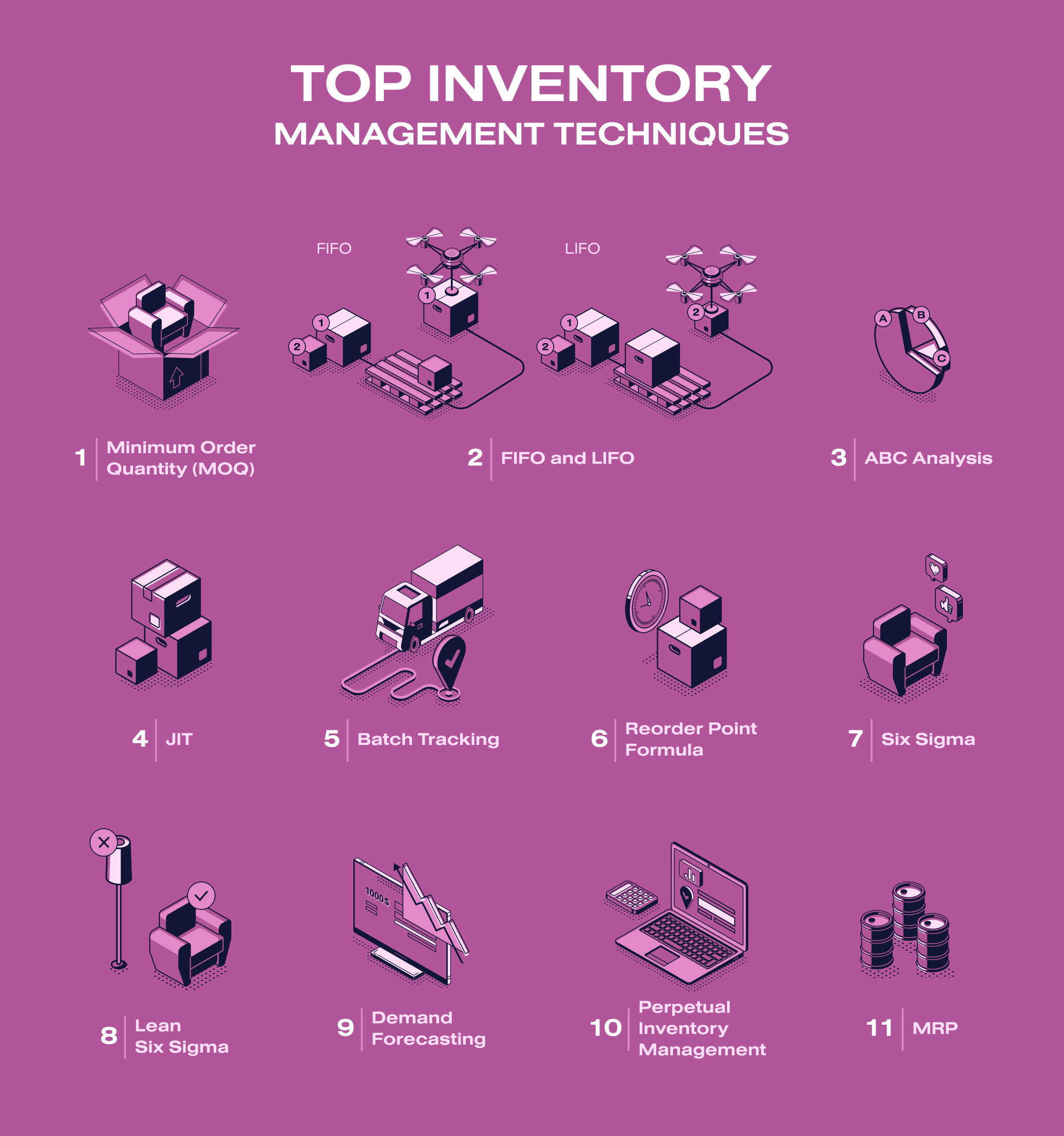

Top Inventory Management Techniques

As soon as merchants invest significant amounts of money in their inventory, it’s crucial to leverage smart and effective inventory management techniques to order and store optimal counts of goods as well as easily track and deliver them to the right place and at the right time. The choice of inventory control techniques greatly depends on your specific business needs. There’s no one-fits-all solution. Read about the most widespread inventory control methods and choose what fits you best.

#1 Minimum Order Quantity (MOQ)

MOQ is the fewest number of product items a supplier can sell to a single business at once. Some manufacturers sell goods to wholesale traders in bulk who then sell those goods to retailers based on a Minimum Order Quantity. And then customers can buy one or two items of a product.

#2 FIFO and LIFO

FIFO stands for “first in, first out” and is a technique that implies that the first product items in your inventory should be sold first so that you can keep inventory fresh. LIFO stands for “last in, first out” and assumes exactly the opposite — the newest items in your inventory should be sold first.

#3 ABC Analysis

In any store, there are goods that sell better than others. Based on the percentage of your revenues, you can split goods into three categories by using the ABC analysis.

The “A” goods (70%-80% of revenue) represent your bestsellers that require minimum warehouse space and cost.

The “B” items (15-20% of revenue) sell quite well. However, they cost more than “A”s to hold.

The “C” goods (5% of revenue) are your dead or slow-moving stock. It contributes too little to your bottom line.

#4 JIT

JIT stands for “Just-in-time Inventory Management” and aims at maintaining the lowest stock level before the next replenishment. By ordering too many product items, you risk ending up with dead stock. JIT allows you to avoid such problems, eliminate stockpiling, and maximize inventory turnover.

#5 Batch Tracking

Batch tracking allows sellers to group similar items and monitor them along the distribution chain using batch numbers. With batch tracking, you can see where goods come from, how much was shipped, where they went, and when they have an expiration date (if any).

#6 Reorder Point Formula

This formula enables you to determine when you should reorder more stock. The formula looks as follows:

(Average Daily Unit Sales x Average Lead Time in Days) + Safety Stock.

With the formula, you’ll be able to order the right amount of goods every month and stop suffering from market slumps or spikes.

#7 Six Sigma

Six Sigma is a data-driven method aimed at reducing excessive inventory as well as obsolete write-offs. By having the correct inventory that meets demand, you can reduce variance and waste problems.

#8 Lean Six Sigma

This technique amplifies Six Sigma but its main focus is increasing standardization and removing waste and items that don’t offer value to customers.

#9 Demand Forecasting

As the name implies, the technique is based on predicting what goods, when, and in what quantity your customers are going to buy. You can forecast demand by relying either on guesses or on recent sales data reports.

#10 Perpetual Inventory Management

This is a technique for estimating your inventory continuously in real-time based on electronic records about purchases and shipments rather than physical inventory.

#11 MRP

MRP stands for Materials Requirements Planning and is based on calculating the components and materials necessary to manufacture a product.

The list of efficient inventory management techniques could go on but we briefly covered the most widespread ones. And now, let’s move on to inventory management KPIs that will help you monitor your stock and make smart decisions about it.

Inventory Management KPIs

Inventory management KPIs (key performance indicators) are metrics used to get information about turnover, costs, demand, revenue, sales, and more to improve your inventory management.

KPIs let you enhance the production/purchasing processes, evaluate the impact of inventory on your business performance, and analyze how close you are to attaining your goals. However, tracking various KPIs manually is time-consuming and complicated. This is where inventory management software comes at hand. With the right tech solution, you’ll be able to manage your inventory more efficiently, while making your customers happy and increasing your bottom line.

Inventory Management Software: What Is It and How to Choose the Proper System

Modern inventory management systems provide capabilities for efficient goods management across the company and your global supply network. They allow you to get rid of the guesswork by matching demand and supply and consequently increase your sales and revenues. Such solutions also allow businesses to reduce human error, which is extremely important since statistics show that it’s the number one issue in warehouses.

The key benefits of using such software are:

- Automated inventory management

- Reducing human error

- Increased productivity

- Enhanced inventory planning

- Avoiding overselling and out-of-stocks

- Reducing business costs

- Ensuring readiness for peak/holiday seasons

- Higher profitability

Choosing the right inventory control system is a big task for any merchant. You need to be strategic and allocate enough time to find the solution to best fit your needs. There are plenty of tools on the market, so you should know what to consider when opting for this or that system. Here’s the list of features to look for in a reliable inventory management system.

- Usability to simplify your inventory management process instead of making it more complicated

- Automated inventory tracking to easily monitor the status of finished goods or raw materials

- Barcode scanning to put an end to data errors, enable paperless documentation and speed up stock refill

- Perpetual updates to ensure inventory counts are live and prevent ordering out-of-stock items by customers

- Integrations to streamline your business processes and have all management tools at hand in the same place

- Analytics to have a glance at the most essential metrics for your business and improve performance

- Accessible support to ensure you aren’t alone when any tech issues arise.

Conclusion

Effective inventory control is the heart of your business. By managing your stock wisely, you get a chance to grow your business in confidence without risking your investments. And a reliable tech solution will let you improve the way you track your inventory, reduce human error, and scale your business successfully.